Curved Corner Frame Construction and Background Installation

By Kevin N. O'Brien Peoria, IL

|

Introduction The surfaces for this background installation were finished basement walls. As a result, one of the project goals was to minimize the number of holes that needed to be drilled into the walls themselves. To meet this goal necessitated the creation of a freestanding frame with the background mounted prior to hanging. The shape of the O scale layout is a L shape with a single curved corner. One wall is 10' and the other 12'. This mounting technique draws on some of the ideas presented in articles by Ken Spelke entitled "Frame Construction and Mounting" and also by Hal Estill entitled "How to Install a Curved Corner Background". |

|

Selecting the Proper Backdrop Size Clearly, the dimensions called for in this installation were not going to be accommodated by a single backdrop. The question was how many images would be required and at what length. The fact that it was an O Scale Layout dictated that the 36' backdrop height would be appropriate. The first step of determining the number of backdrops is to calculate the continuous length required by the backdrop. This was accomplished using a spreadsheet and the product information contained in the Backdrop Warehouse site. A sample of the spreadsheet follows. Note the deductions necessary to remove the labels and overlap.

|

|

|

|

Frame Construction Due to the length of the two frames that will be joined by the curved corner, the ability to find straight lumber was going to be a challenge. The final lumber purchase list follows:o 2 1" x 3" x 12' for the frame top and frame bottom for the 12" wall o 2 1" x 3" x 10' for the frame top and frame bottom for the 10" wall o 13 1" x 2" x 28 ¾" for the vertical frame supports The overall vertical dimension of the frame is 34 ¾". The reason for the odd number is that the printed surface on a 36" x 10' backdrop is in fact only 34 ¾". The intention of this construction was to only have the printed surface showing; therefore, the frame was constructed to accommodate only the printed area. The lumberyard does not actually carry lumber in the 1" x 3" dimension for the lengths of 10' and 12'. To accomplish this some 1" x 6" boards were cut in half at the lumberyard for a nominal fee. This was done in an effort to maintain the straightest resulting board possible. Interestingly, the board did warp slightly the moment the saw blade finished the cut and so steps were required throughout the construction to get the frame square. |

|

Wall Frame Assembly The frames were assembled using corner brackets that can be found in aluminum or steel at most home improvement stores. In addition, some steel

plates with screw holes (see picture Backdrop Mounting Bracket

Installation) were used to anchor the outside of the vertical supports to

the top and bottom frame boards to ensure that the frame was rigid and

resisted warping.

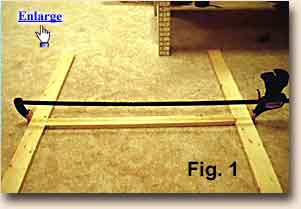

The most successful and fastest method to create the frame was to use

a long clamp to hold the vertical frame board to the two horizontal boards

before attaching the corner brackets. This can be seen in

Fig. 1. All corner bracket holes were

predrilled to avoid splitting the wood. This step is repeated until the

entire single framing element is complete. For added strength wood glue

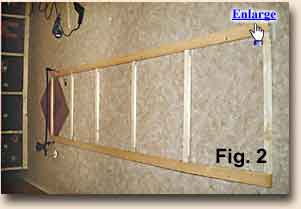

was used at each contact area. Once complete the frame should resemble the

picture in Fig. 2. In addition, some steel

plates with screw holes (see picture Backdrop Mounting Bracket

Installation) were used to anchor the outside of the vertical supports to

the top and bottom frame boards to ensure that the frame was rigid and

resisted warping.

The most successful and fastest method to create the frame was to use

a long clamp to hold the vertical frame board to the two horizontal boards

before attaching the corner brackets. This can be seen in

Fig. 1. All corner bracket holes were

predrilled to avoid splitting the wood. This step is repeated until the

entire single framing element is complete. For added strength wood glue

was used at each contact area. Once complete the frame should resemble the

picture in Fig. 2.  Note you can see the

mounting brackets used to attach the outside vertical supports to the top

and bottom plates. This same construction technique was used to create the

second wall frame. Note you can see the

mounting brackets used to attach the outside vertical supports to the top

and bottom plates. This same construction technique was used to create the

second wall frame.

|

|

................ |

|

Frame Attachment at the Corner

|

|

|

|

Hanging the Frame Prior to hanging the frame, mounting brackets need to be attached to the back of the frame. This was done using the same four holed steel plates used to secure the outside of the frame. The mounting bracket will

look like Fig. 10. Hold the

frame up to the designated area and mark the bracket holes with a pencil.

Make sure that the frame is flush with both walls in the corner. Remove

the frame and drill holes to accommodate dry wall mollies. Sink the

mollies into the holes at all locations. Bring the frame back into the

installation position and install screws into all bracket locations.

The installation is now complete and an immediate impact to the layout

should be seen. Illustrations of the early stages of layout construction

with the backdrop in place can be see in the

before Fig. 11 and after pictures. The mounting bracket will

look like Fig. 10. Hold the

frame up to the designated area and mark the bracket holes with a pencil.

Make sure that the frame is flush with both walls in the corner. Remove

the frame and drill holes to accommodate dry wall mollies. Sink the

mollies into the holes at all locations. Bring the frame back into the

installation position and install screws into all bracket locations.

The installation is now complete and an immediate impact to the layout

should be seen. Illustrations of the early stages of layout construction

with the backdrop in place can be see in the

before Fig. 11 and after pictures.

|

|

Can you write an Article If you would like to write an article on how you installed your BackDrop, we are interested. Good articles like this one will be included on our web site. Payment is typically around the cost of the backdrops used (limit $300) but may be more or less depending on the number of backdrops involved and the quality of the article.

Many well lighted photos are a must. We may submit good articles for review at major model railroad magazines. All photos and text are your property (except we have the right to use any sent to us on this web site) and arrangements for publication and payment are between you and the magazine. We will match the payment from the magazine up to $200 as long as our company is mentioned as the supplier of the backdrops. We can retouch and improve your photos for no additional charge.

|