USING RUBBER CEMENT on an EXISTING LAYOUT

By John Thompson, Colorado

|

For my Hon3 version of the Rio Grande Southern, I wanted a visually stunning backdrop of Lizard Head for my model of the wye at the summit of Lizard Head Pass. Backdrop Warehouse had exactly what I needed, and after some research, I decided the Rubber Cement method mentioned on the website would work well with the curved backdrop support I had installed. Hereís how I installed the photorealistic backdrop on my railroad. In Fig. 01,

|

|

Materials

Figure 2 shows the materials used. A straightedge and either a sharp utility knife (use a brand new blade) or a rotary cutter works well to cut the backdrops to the necessary size. |

| Application of Rubber Cement

Figure 3 shows the application of the glue Ė Iím applying the second coat in this shot. A strip of glue along the top, bottom, and middle for 24" tall backdrops or larger, is all that is needed to hold the backdrop to the support board.

|

|

................ |

|

Measuring and Cutting

Figures 4, 5 and 6 show the cutting of the backdrop to fit the vertical space. In figure 4,

|

|

. |

Install backdrop In figure 7, I have applied a third coat of rubber cement on the edge of the support board, as well as about a foot in from the edge on the top, middle, and bottom. Again, the glue dries incredibly fast, so you can only work a foot or two at a time. I align the edge of the backdrop with the edge of my support board and use light hand pressure to adhere the backdrop to the board (Fig. 8), making absolutely sure Iím parallel to the horizon Ė a slight mistake here can lead to an unsightly and aggravating rise over the length of the backdrop. I then unroll the backdrop a short distance (Fig. 9). |

|

I use the clean paint roller to go over the surface of the backdrop to adhere the glue (Fig. 10), and roll the backdrop back over the just-glued section so I can apply another foot or so of glue (Fig. 11). Go easy on the paint roller Ė a few passes are sufficient to get the backdrop to lie down. Figures 12 and 13 show the continuation of the process, note that a helper makes the installation much

easier.

|

|

||||

|

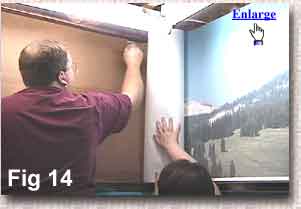

Applying the backdrop into a corner works the same way as on a flat surface with the rubber cement technique. Apply the glue a foot or so over on the top, middle and bottom glue "bases"(Fig. 14), unroll the backdrop, and carefully press out with the paint roller (Fig 15, Fig. 16). The corner on my layout is also the focal point, and some planning was done to make sure Lizard Head was at the center................ Applying the backdrop into a corner works the same way as on a flat surface with the rubber cement technique. Apply the glue a foot or so over on the top, middle and bottom glue "bases"(Fig. 14), unroll the backdrop, and carefully press out with the paint roller (Fig 15, Fig. 16). The corner on my layout is also the focal point, and some planning was done to make sure Lizard Head was at the center................ |

|

|

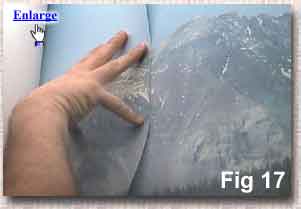

Seams Matching seams takes some planning and care, however itís not too difficult to get a good match. This method overlaps the backgrounds, allowing for good alignment. Cut the overlapping backgroundís edge in a couple inches to minimize edge distortion and ensure a good match. Begin your matching by aligning major features of the backdrop Ė in Figure 17 and 18, Iím using the mountain and the trees to align the backdrop. Lightly tape the backdrop exactly where you want it, and double-check your seam for a good match (Fig. 19). Be sure to "fold over" the edges of the tape so you can remove them later. Once the backdrop is aligned, glue and apply the backdrop to the support board, but leave the taped overlapping section unglued at this time. This can be seen in figures 20, 21, and 22.

|

|

.............

|

||||

|

Once the glue has dried on the rest of the backdrop, you can carefully remove the tape from the overlapping section. Next, apply a single length of tape on the bottom backdrop piece; making sure the tape edge facing the overlapping section is about 1/32" inside the overlap when you press the overlapping section flat, as seen in figures 23, 24 and 25. This is your glue line, and will keep stray rubber cement from getting on the visible portion of the lower backdrop. Apply rubber cement on the face of the lower backdrop (fig. 26) as well as the back of the overlapping backdrop (Fig. 27) and allow to dry until tacky to the touch Ė 30 minutes is more than sufficient. Once it is dry, you can carefully remove the tape (take extra care and work slowly)(Fig. 28). Press the top layer onto the bottom layer (Fig. 29) and gently roll the seam with the dry paint roller. Youíre done!

|

|

Figures 30 and 31 show some benchwork, roadbed and track in place. Even with no foreground scenery, the backdrop lends tremendous realism to the scene. All thatís left is to add a few hills and trees and some spot lighting and the scene will be complete.

|

|

|

Can you write an Article If you would like to write an article on how you installed your BackDrop, we are interested. Good articles like this one will be included on our web site. Payment is typically around the cost of the backdrops used but may be more or less depending on the number of backdrops involved and the quality of the article. Many well lighted photos are a must. We may submit good articles for review at major model railroad magazines. All photos and text are your property (except we have the right to use any sent to us on this web site) and arrangements for publication and payment are between you and the magazine. We will match the payment from the magazine up to $200 as long as our company is mentioned as the supplier of the backdrops. |